High-resolution, Real-time Terahertz imaging

with TeraCascade 1000

Our partner

Lytid is proud to present the successful research implementation reached in collaboration with our partner IMS, University of Bordeaux. The Nanoelectronic group of IMS, has developed a research line focused on the implementation of a large panel of high-end THz technologies and systems for inspection, non-destructive testing and sensing applications. The long standing partnership between Lytid and the Nanoelectronic group of IMS has led to several collaborations and a common PhD program on TeraHertz technologies for imaging application.

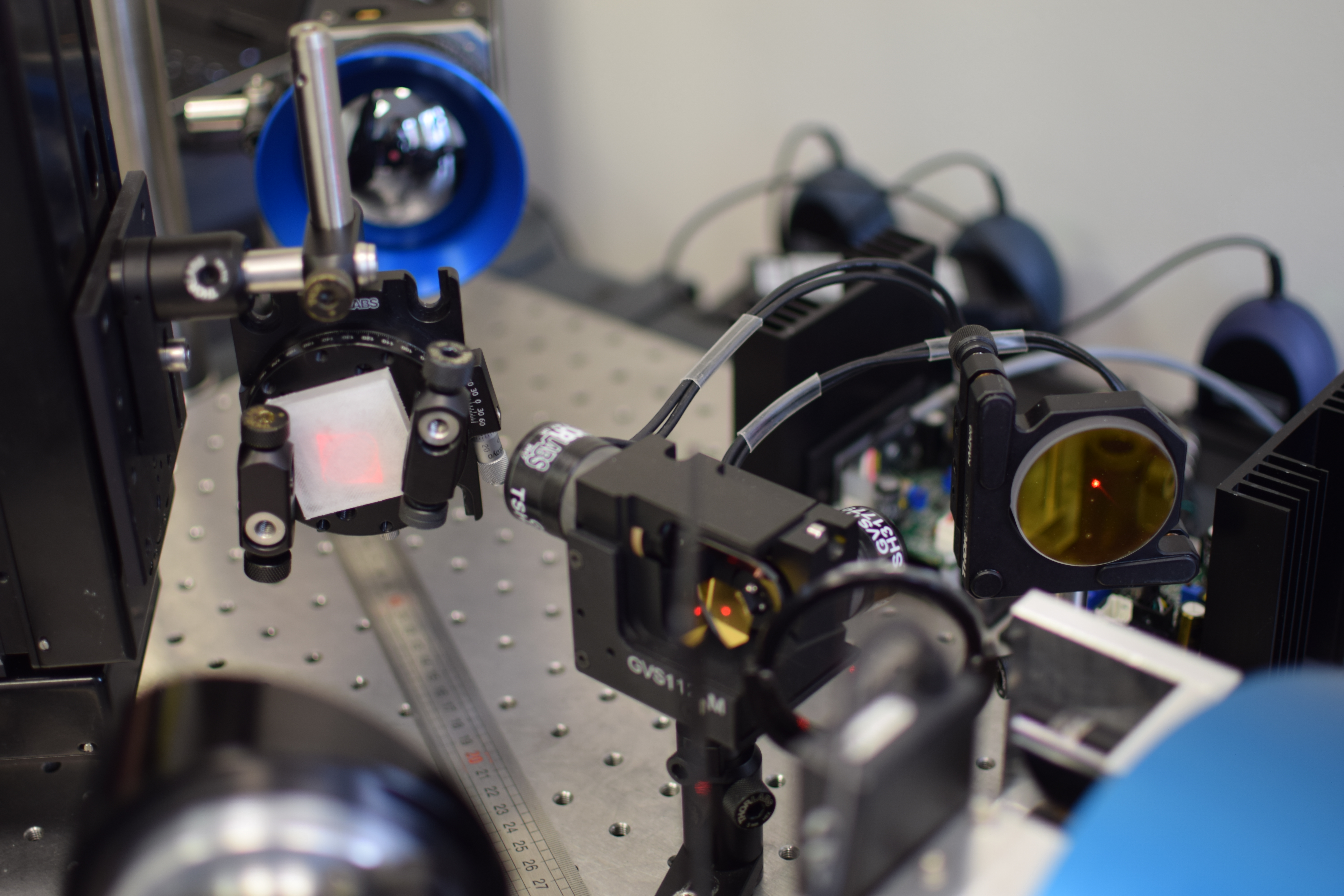

THz beam-steering unit for flexible illumination patterns

The collaboration between the Nanoelectronic group of IMS and Lytid aims at the development of a real-time, high-resolution THz imaging system overcoming the limits of classical full-field imaging setups.

Such imaging techniques require the sample to be fully illuminated for the acquisition of a real-time image stream at a video-rate thanks to a multi-sensor detector. This technique is limited by a relatively low Signal-to-Noise Ratio (SNR), since the THz radiation power is spread over a large sensor area. The emergence of mW level THz sources based on Quantum Cascade Lasers (QCL), like TeraCascade1000, paved the way for increasing SNR real-time imaging while giving access to the spatial resolution defined by the THz emission frequency (2.5 THz in our case). However, the inherent strong coherence of THz-QCL emission carries a drawback: path differences through the imaging system cause unwanted interference fringes at the detector plane, resulting in highly impacted and unstable images.

In this context, the Nanoelectronic group of IMS and Lytid developed an innovative imaging setup, comprising a programmable beam-steering unit able to generate a homogenous and flexible illumination pattern, thus solving the limitation imposed by the emission’s coherence. The optical setup is powered by few mW of 2.5 THz radiation from TeraCascade1000. The radiation propagates through the beam-steering unit, where the suitable illumination pattern is created by fast steering of the laser beam thanks to a galvanometer mirror. After transmission or reflection through the sample, the image is acquired by a bolometric camera equipped with a THz objective, TeraLens (40mm – f/0.83 – x0.22). The frame rate of the detector is adjusted to collect an image after a complete pattern is generated, allowing for increasing SNR in real-time imaging. In addition, the beam-steering unit being fully programmable, the illumination pattern can be tailored to fit different sample dimensions and applications.

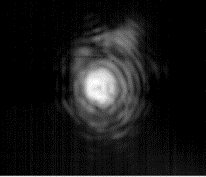

Without illumination shaping

With illumination shaping

Here beside, the comparison between the THz illumination profiles without and with homogenization. THz beam profile shows visible interference fringes caused by multiple reflections on optical components of a typical imaging setup. Those artifact limitations are overcome thanks to the programmable steering-unit developed by IMS in collaboration with Lytid.

This innovative technique allows the generation of homogeneous and customized patterns to fit specific applications, different sample dimensions, and defined detection requirements. On the right, an example of custom pattern that can be generated with the programmable beam-steering unit.

Applications and results

The innovation of a programmable homogeneous illumination pattern opens up several applications with increased performance. The technique has been tested on different variants of real-time illumination schemes. The following results illustrate that this technique gives exceptional results either in linear scan configuration or in full-field imaging acquisition. Moreover, the flexibility of the system gives access to countless possibilities and applications.

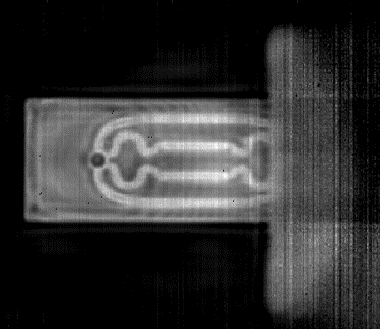

High resolution and increased SNR with linear scan

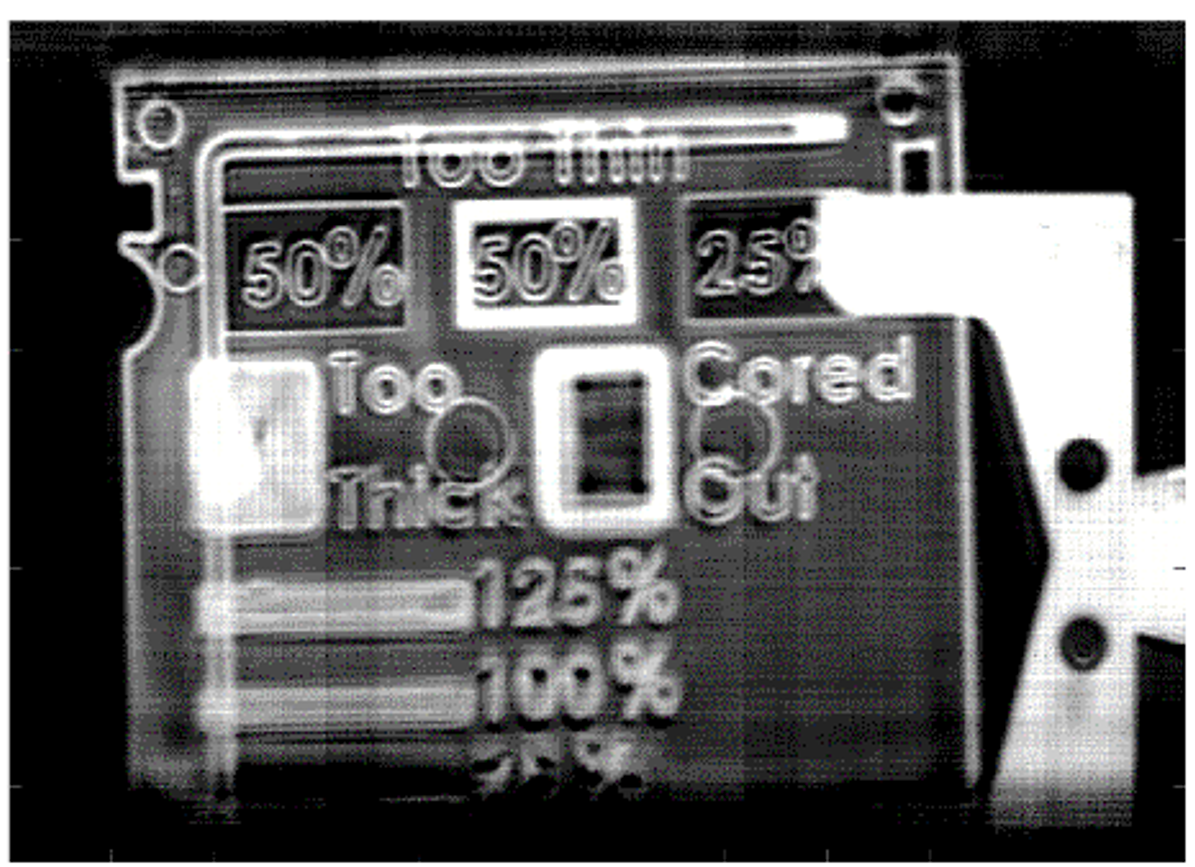

The imaging setup is here used in scan mode. The homogenous illumination pattern remains static and a polypropylene sample with various characteristic extrusions is linearly scanned in front of it. The transmitted radiation is then collected by the bolometric camera. The imaging mode allows high SNR real-time reconstructions with high resolution, demonstrating the suitability of this method for non-destructive investigation in industrial applications.

Full- field homogenized real-time imaging with 2D pattern

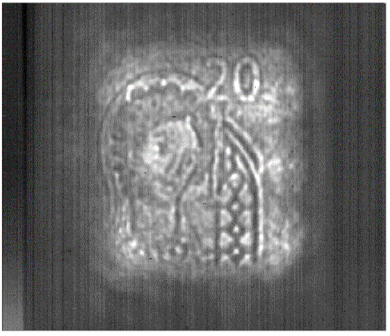

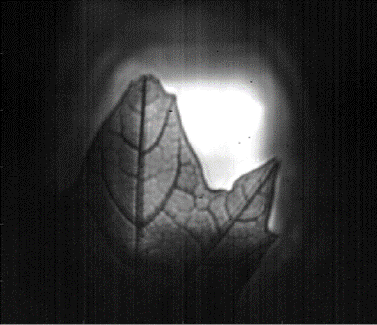

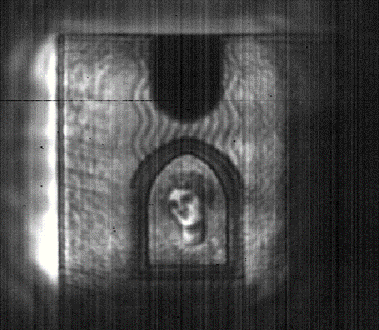

Here below some examples of full-field images. The THz pattern illuminates different samples and the transmitted radiation is collected by a bolometric camera. The illumination pattern is programmed in order to fit the specific size of each sample. The typical acquisition time for the following images is only 160 ms and attainable resolution at 2.5 THz is 250 micron.

![]() Watermark on 20€ bill

Watermark on 20€ bill

![]() 3D printed maze with metal bead

3D printed maze with metal bead

![]() Tree leaf

Tree leaf

![]() Holographic strip on 20€ bill

Holographic strip on 20€ bill

![]() 3D printed ceramic microfluidic chip

3D printed ceramic microfluidic chip

Tomographic reconstruction

![]()

In this example, real-time full-field images of a foam cube with metallic inclusions (needles and metal bead) are collected for different sample orientations. The images are then processed to obtain a 3D reconstruction of the sample.