Non-contact, non-invasive packaging inspection

In contrast to X-ray inspection with a high risk of altering the properties of sample under test, terahertez radiation is harmless for people who work with it. Lytid’s NDT Radar solution provides a tailored non-contact non-destructive and non-invasive alternative, suitable for a wide range of application in different fields, including food and pharmaceutical industries.

Pharmaceutical packaging

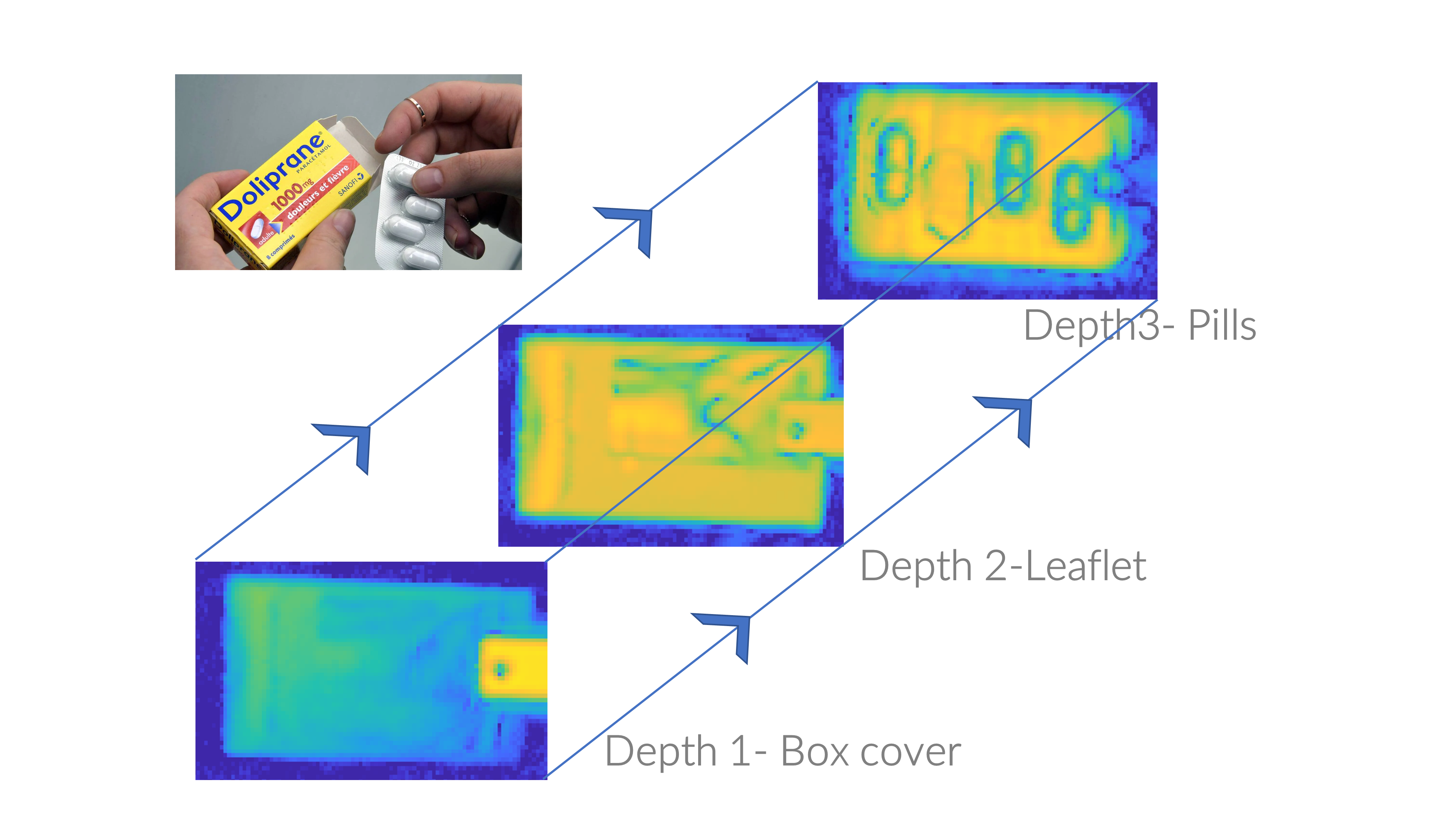

It is obligated to insert a leaflet inside a pharmaceutical package. But how can we verify the insertion of leaflet once the package is sealed ? While X-ray is forbiddend to avoid any chemical change, Lytid’s NDT radar can privide a solution. As shown below, NDT radar solution provides information in different depths, from the surafce of the box, leaflet inside and pills in the package.

In-depth imaging of sealed pharmaceutical packaging

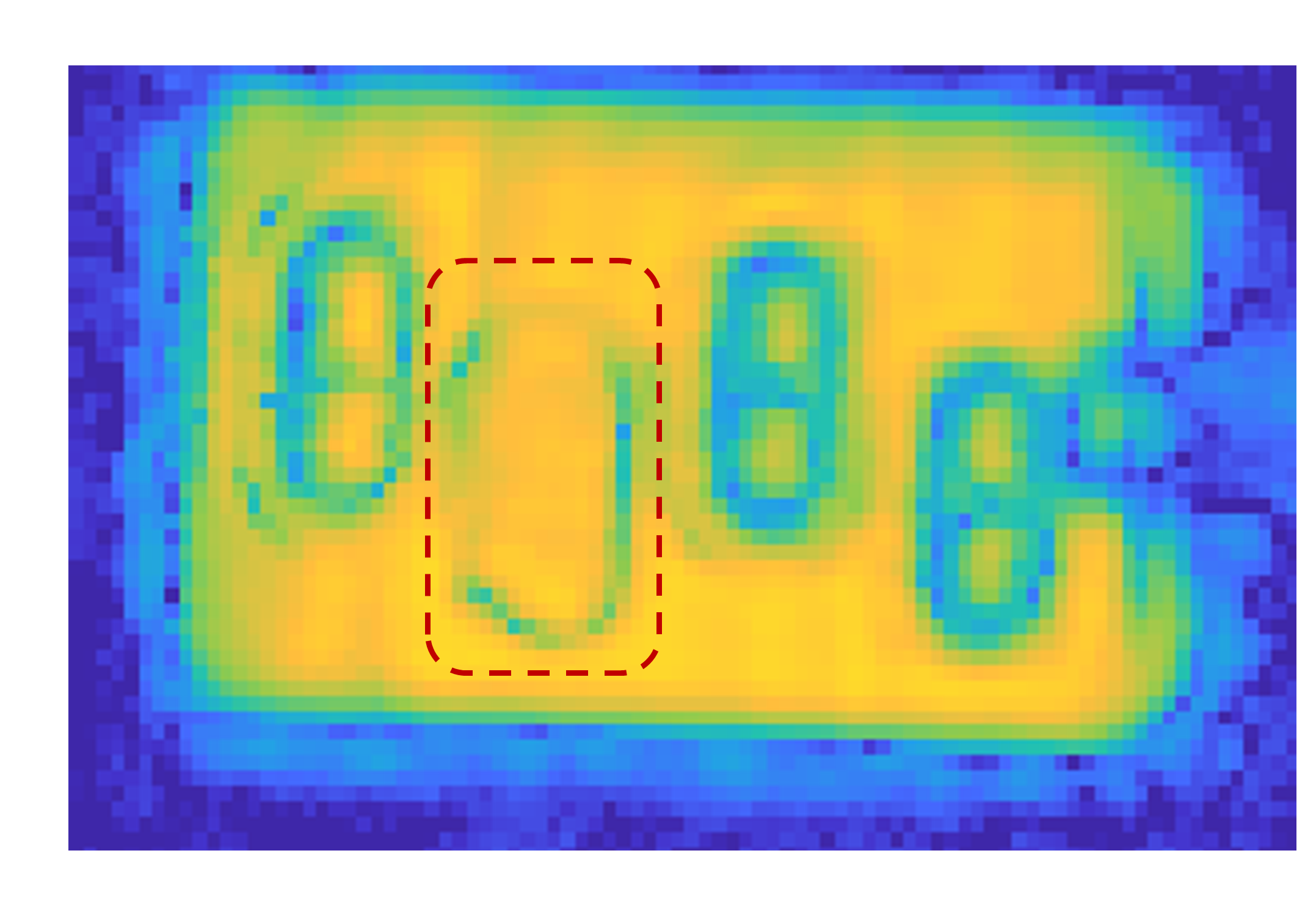

Missing tablet inside blister package

While ensuring a high inspection cadence, problematics of interest revolved around the assessment of the leaflet presence and position, along with the monitoring of sealed pills wrapping. Through in-depth evaluation with longitudinal resolution, NDT radar solution successfully depicts such features, along with the assessment of the cardboard packaging sealing integrity and complemented by the count of the individual pills. This last point is featured through the unequivocal visualization of the missing pill on the faulty sample.

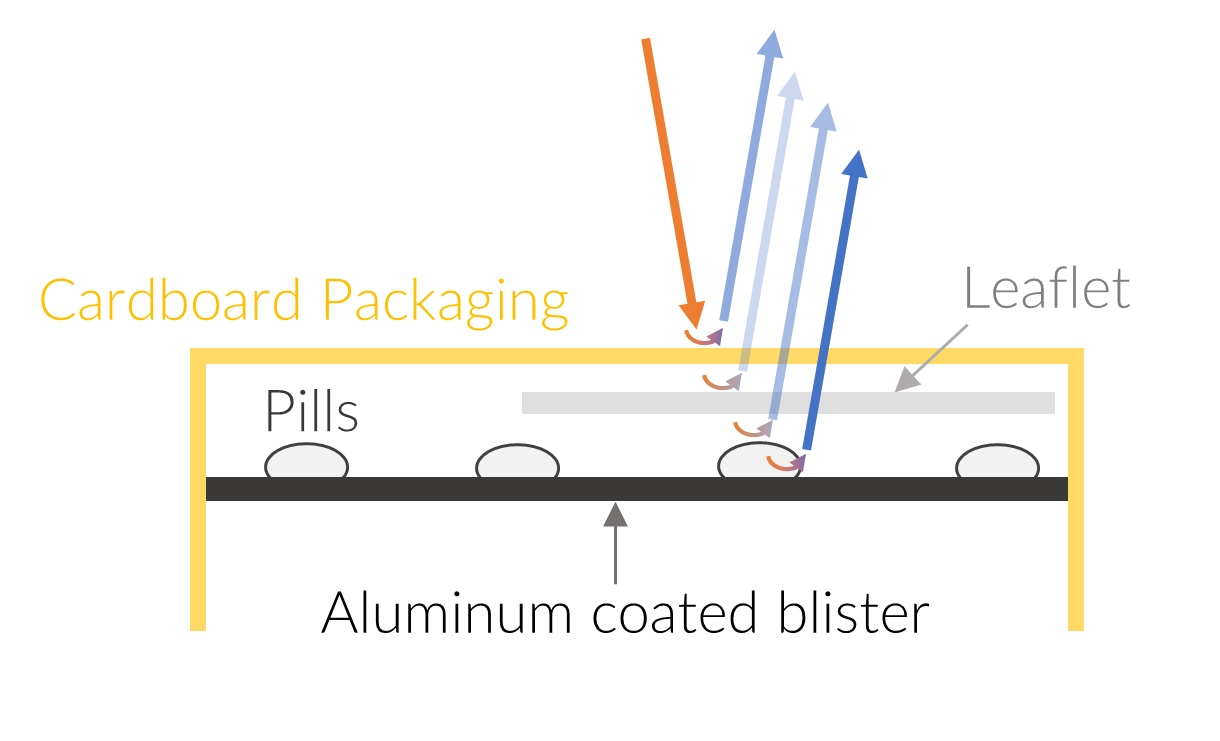

Diagram of the operation principle of pharmaceutical packaging inspection

For such layered samples, the signal emitted from the system penetrates the sample while a fraction of the power is reflected from each interface, enabling suitable contract over each element. Based on the reflected signal, longitudinal information on the sample can be achieved, allowing a 3D recontrsuction. Here, this specific sensing geometry takes advantage of the total signal reflection over the metallic pellicle of blister.

Food packaging inspection

Numerous problematics in food industry remain unfulfilled, such as foreign bodies, impurities detection inside goods and packaging. Terahertz solution represents competitive advantages in differnet aspects to overcome these difficulties : firstly, being non-ionizing radiation, THz waves ensure a hazardless handling and operation; secondly, THz waves possess high sensitivity to water content and high penetration capacity into non-metallic and non-polar materials at the same time.

Impurities and foreign bodies detection in chocolate

Nowadays, although several established technologies have been successfully demonstrated for metallic foreign body detection, non-metallic materials such as polymers, glasses remain problems to be solved. Through its non-contact, non-invasive approaches, Lytid’s NDT radar solution ensures a highly contrasted sensing for such problematics and successfully pursue the detection of much more challenging inclusion. Specifically, the assessment of transparent glass shards among hazelnuts filled chocolate bars represents a challenging inspection requiring enhanced sensitivity.

Chocolate bar filled with hazelnuts

Glasses pieces hidden between the chocolate

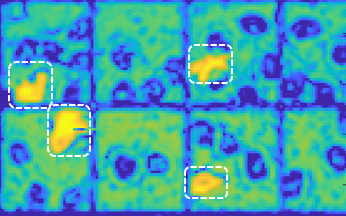

Imaging results as a fonction of depth – GIF

Through the high achieved contrast, a sensitive differentiation of every compound can be offered allowing counts and density assessment for hazelnuts, chocolate volume control, and the targeting of foreign bodies. As shown above, chocolate and hazelnut remain quite transparent to terahertz waves, each foreign body (glass piece) can be well differentiated via such a highly contrasted inspection.

Beyond existing technological achievements, Lytid’s technologies ensures the detection and positioning of non-metallic foreign bodies, through highly contrasted sensing.

Impurities and foreign bodies detection in grain package

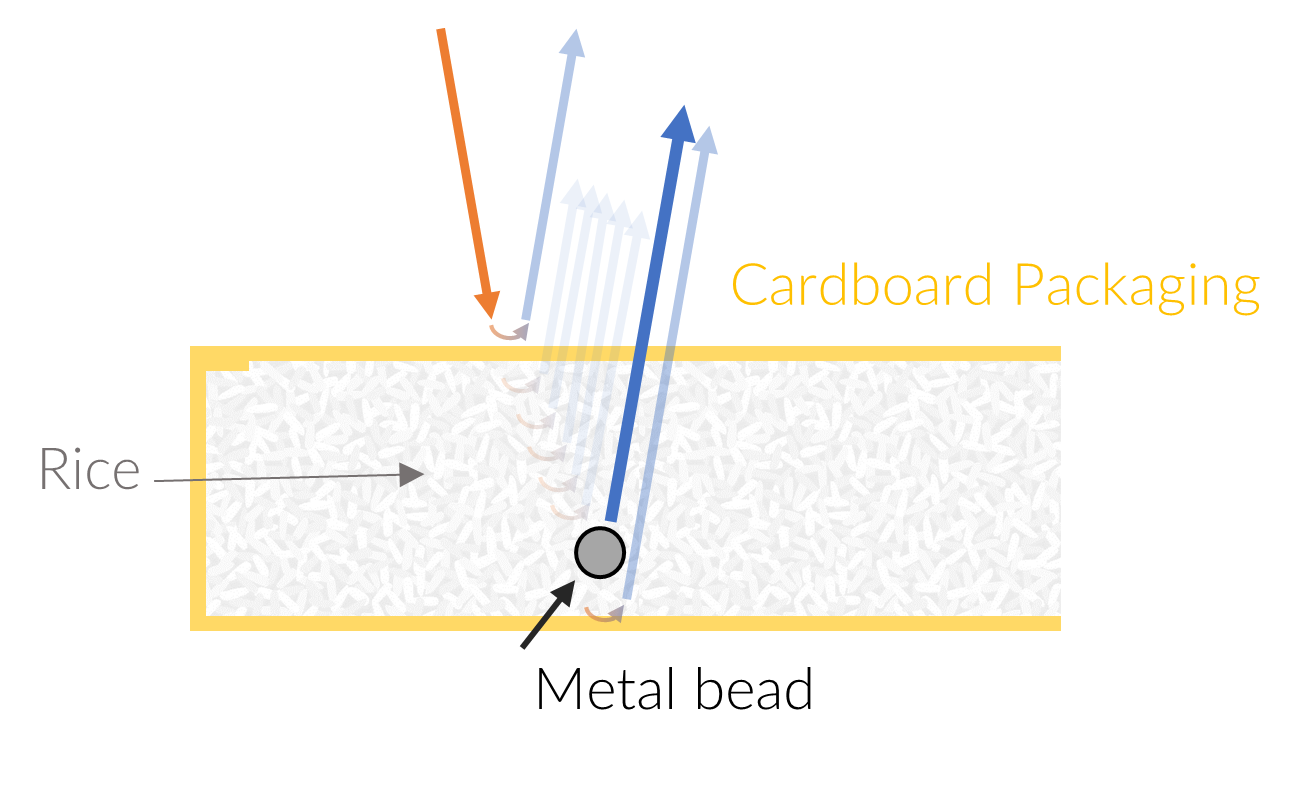

The detection of metallic parts in non-transparent and granular compounds is a challenging operation for the food industry. Lytid’s NDT radar solution allows to operate through sealed packaging for the visualization of such foreign bodies.

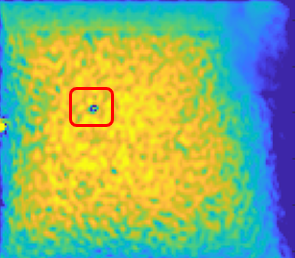

Rice package with metal bead inside

Detection of a metal bead in a sealed rice package

Imaging results as a fonction of depth – GIF

Diagram of the operation principle for the foreign body inspection in a rice package

A high detection rate can be achieved for metallic bodies in the terahertz frequency thanks to their high reflectivity, ensuring simplified observation through sealed packaging.

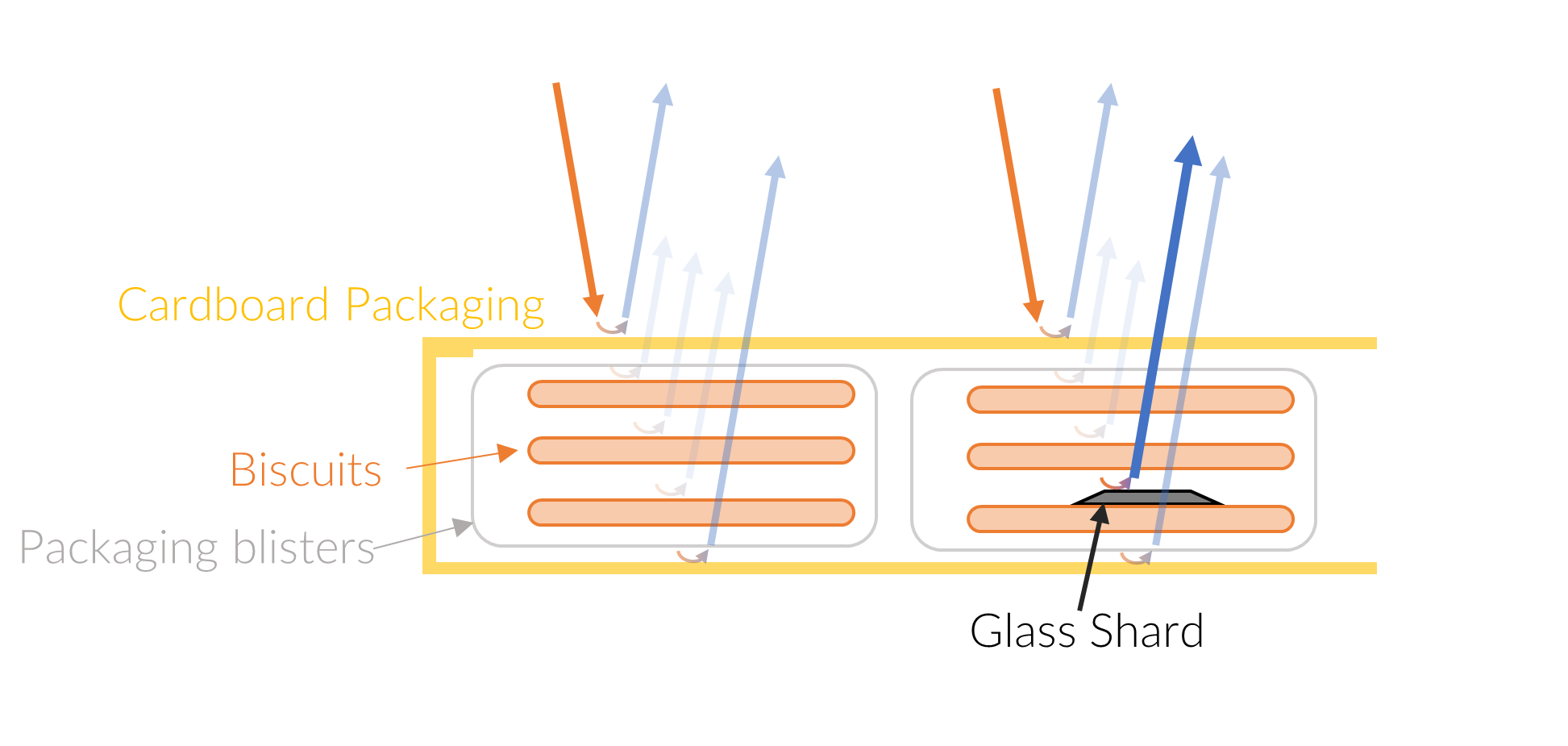

Impurities and foreign bodies detection in biscuit package

The detection of metallic parts in non-transparent and granular compounds is a challenging operation for the food industry. Lytid’s NDT radar solution allows to operate through sealed packaging for the visualization of such foreign bodies.

Biscuit package

Glass detected inside package

Imaging results as a fonction of depth – GIF

Diagram of the operation principle for the inspection inside a biscuit packaging