Corrosion inspection with NDT Radar Solution

A large variety of industrial sectors suffer from corrosion issues, causing undesired high maintenance costs, products obsolescence. Namely, naval and aeronautics sectors are higly impacted, for instance, even early-stage corrosion behind the protective coatingd represents a harmful signal with potential damage risks. Although the inspection of such metal substrates can be performed after the removal of all protective layers, this destructive approach damage the sample under test while the whole process remains time-consuming and expensive.

It is then primordial to detect corrosion traces in early stages in a non-invasive way to anticipate maintenances or parts replacement. Terahertz FMCW radars technologies, as a new supplemnetary tool, enable a non-contact, sensitive, harmless assessment of corroded surfaces through multiple opaque protective layers.

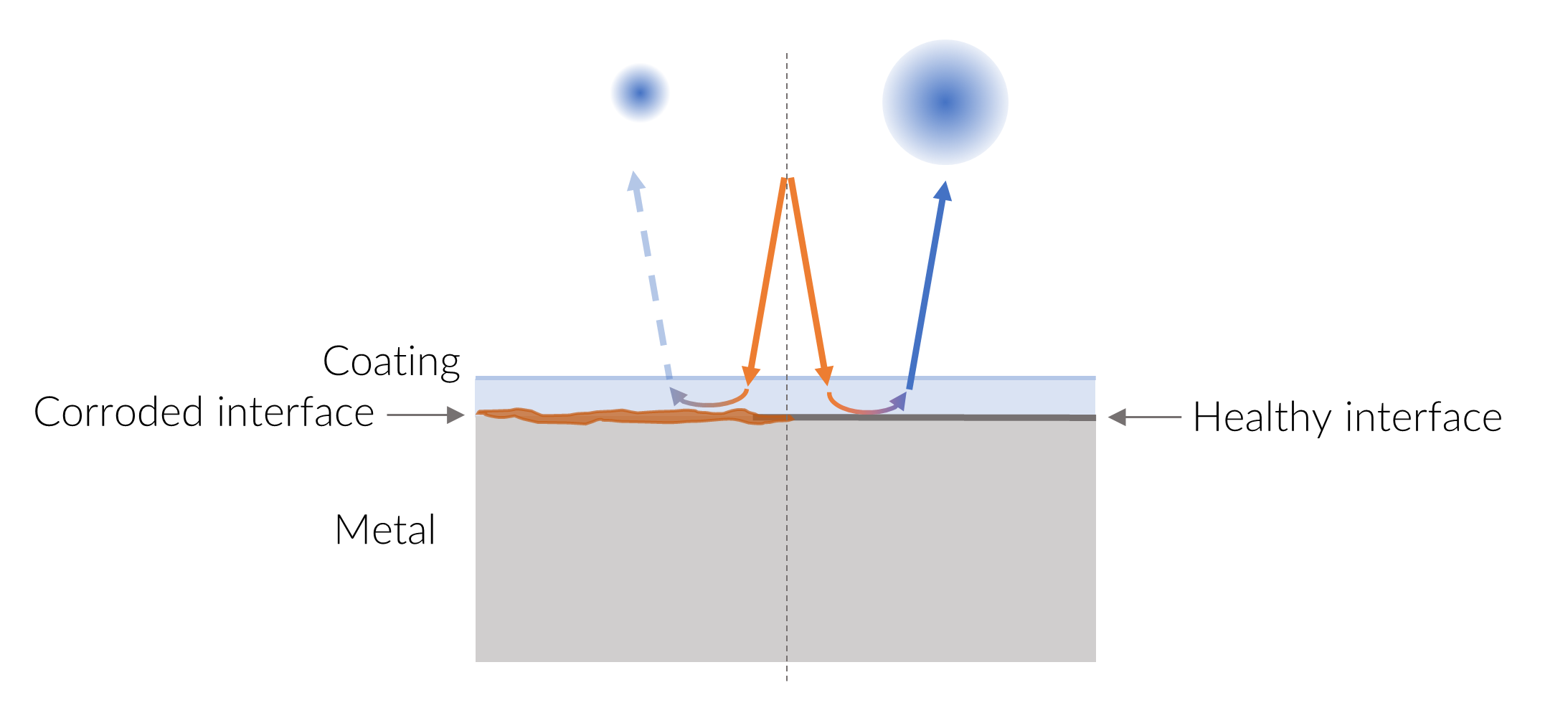

NDT radar inspection principle for early-stage corrosion

Through the subtle reflectivity change of the metallic substrate in presence of corrosion traces, NDT radar solution provides a sensitive measurement tool capable of detecting minor corrosion traces through opaque protective coating layers.

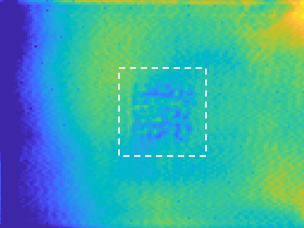

A one-sided inspection of an opaquely protected metallic substrate has been performed using the NDT radar solution. While no corrosion can be observed with visible light, image achieved with Lytid’s NDT radar solution shows clearly corrosion traces (marked with white dot rectangle) behind the coating at the center.

Inline

Non-contact

High accuracy