Non-Destructive Testing (NDT) with Terahertz

Using our expertise in THz, we have pushed the boundaries of Non-Destructive Testing (NDT), a groundbreaking technology that redefines material inspection without compromise.

With benefits inherited from IR and millimeter-waves, THz electromagnetic waves can provide in-depth inspection in a non destructive manner of a wide range of materials ranging from polymers and ceramics, to fibered-based composites featuring complexes geometries such as honeycomb structures. The advantages of THz combined with the capabilities of Frequency Modulation Continuous Wave (FMCW) radar sensors enable 3D inspection and sensing capabilities.

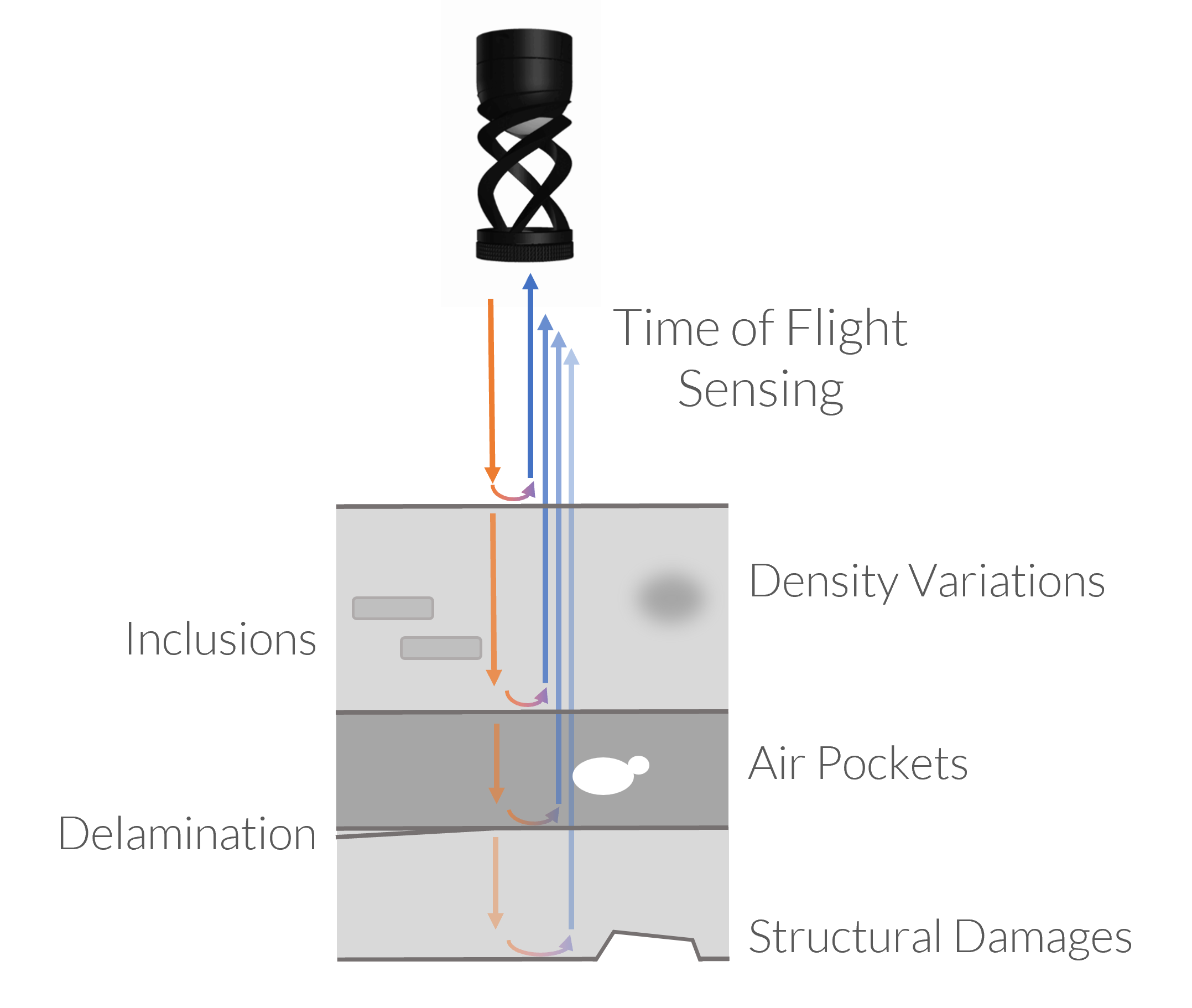

The principle is based on time of flight (ToF) sensing: The emitted THz waves from radar are directed at the materials being inspected, these waves interact with the material. By measuring the time it takes for the reflected waves and echoes, a 3D image of the material’s internal structure is created. This image is then analyzed to detect a wide variety of defects such as density variations, inclusions, delaminations, air pockets and structural damages.

Principles of 3D inspection through FMCW radar and time of flight sensing

Moreover, the highly reflective aspect of metallic substrate or carbon fibered doped substrate still makes THz sensing perfectly suitable for many applications such as corrosion sensing under protective paint layers. The ability of THz NDT to see through objects in 3D, its sensitivity to a wide range of materials, and its safety make it a valuable tool for ensuring the quality of products in many industries.

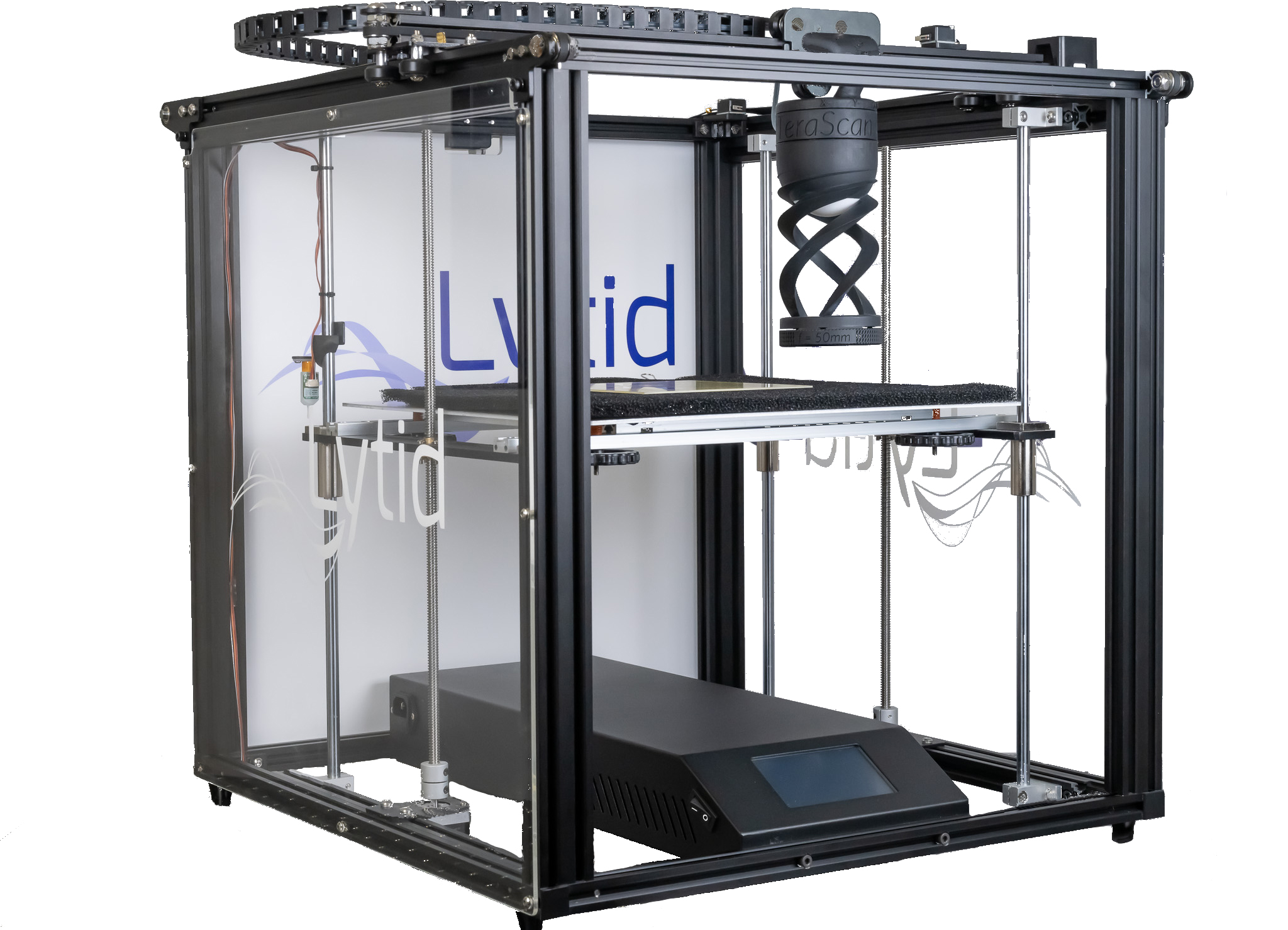

Cost effective solution : TeraScan

TeraScan product line offers unparalleled versatility and performance

> Off-line inspection

> Modular

> Contact-less

> Non-invasive

TeraScan Frame

TeraScan Cobot

TeraScan Frame

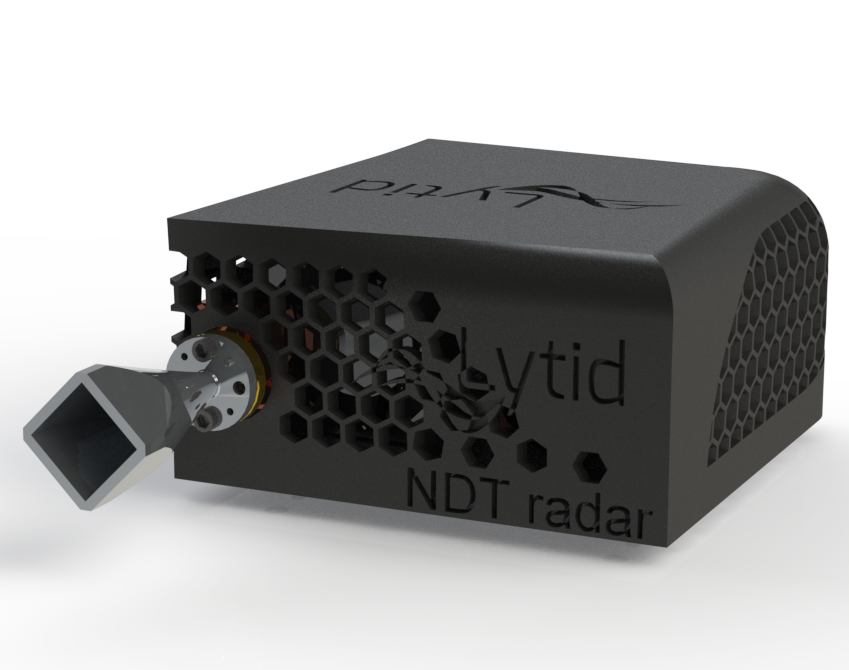

Sensors for in-line inspection

Schottky diode based terahertz technology

> Contact-less

> In-line inspection

> High penetration

> Ultra-compact

High material penetration

Up to tens of cm

High inspection rate

Several thousands traces/s

High resolution 3D imaging

Sub-mm resolution