TeraScan

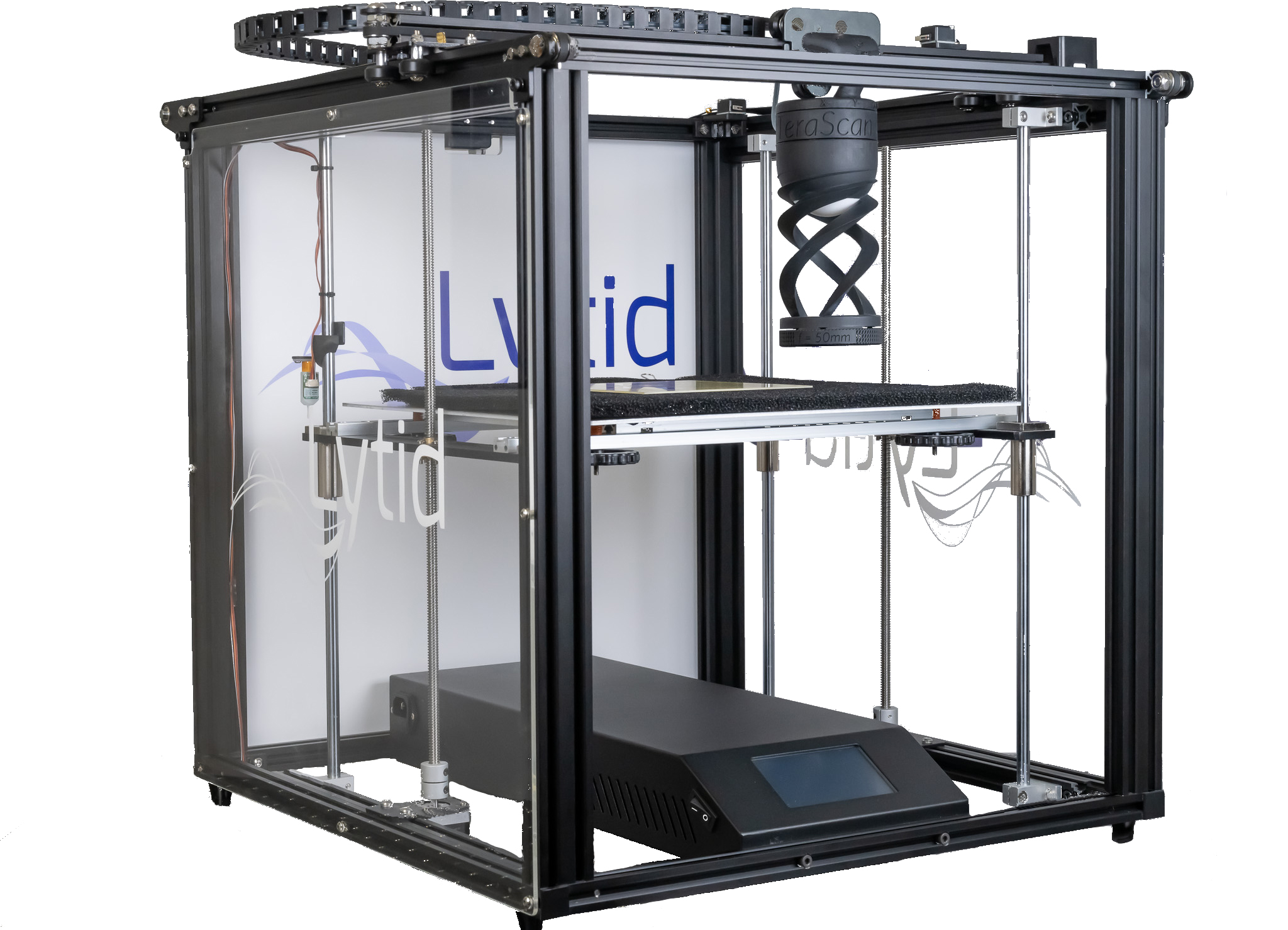

In-depth 3D modular THz NDT scanner based on radar technology

Our Terascan product line uses non-contact sensing technology to deliver unrivaled detection performance and enhance the capabilities of Terahertz (THz) technologies for Non-Destructive Testing (NDT). With its fully automated and modular design, this all-in-one tool is an affordable solution that empowers our customers to explore the potential of THz sensing.

THz Radar transceiver system

Fully automated

3D THz scanning properties

User-friendly

Non-destructive testing with Terahertz

Using our expertise in THz, we have pushed the boundaries of Non-Destructive Testing (NDT), a groundbreaking technology that redefines material inspection without compromise.

With benefits inherited from IR and millimeter-waves, THz electromagnetic waves can provide in-depth inspection in a non destructive manner of a wide range of materials ranging from polymers and ceramics, to fibered-based composites featuring complexes geometries such as honeycomb structures. The advantages of THz combined with the capabilities of Frequency Modulation Continuous Wave (FMCW) radar sensors enable 3D inspection and sensing capabilities.

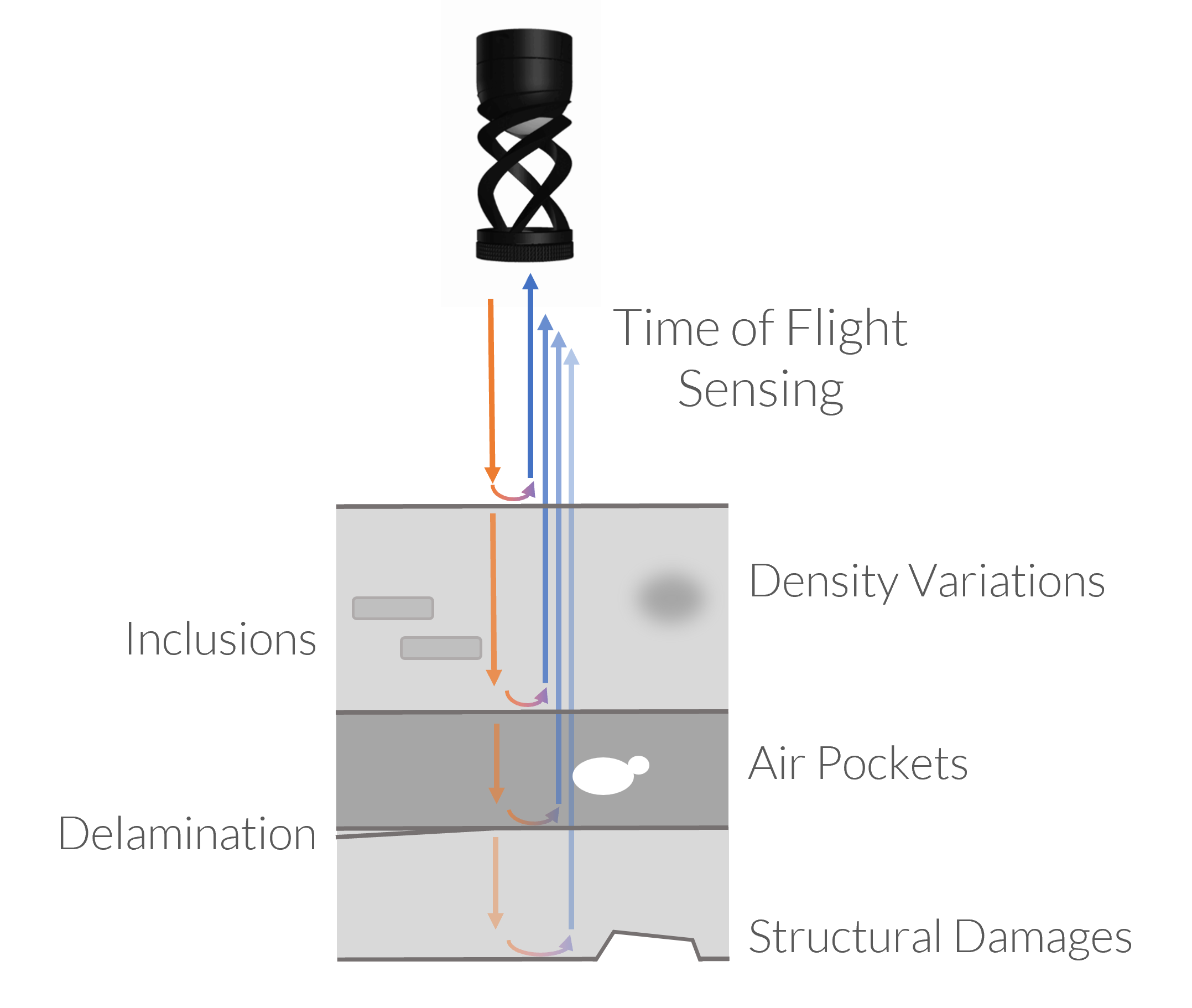

The principle is based on time of flight (ToF) sensing: The emitted THz waves from radar are directed at the materials being inspected, these waves interact with the material. By measuring the time it takes for the reflected waves and echoes, a 3D image of the material's internal structure is created. This image is then analyzed to detect a wide variety of defects such as density variations, inclusions, delaminations, air pockets and structural damages.

Principles of 3D inspection through FMCW radar and time of flight sensing

Moreover, the highly reflective aspect of metallic substrate or carbon fibered doped substrate still makes THz sensing perfectly suitable for many applications such as corrosion sensing under protective paint layers. The ability of THz NDT to see through objects in 3D, its sensitivity to a wide range of materials, and its safety make it a valuable tool for ensuring the quality of products in many industries.

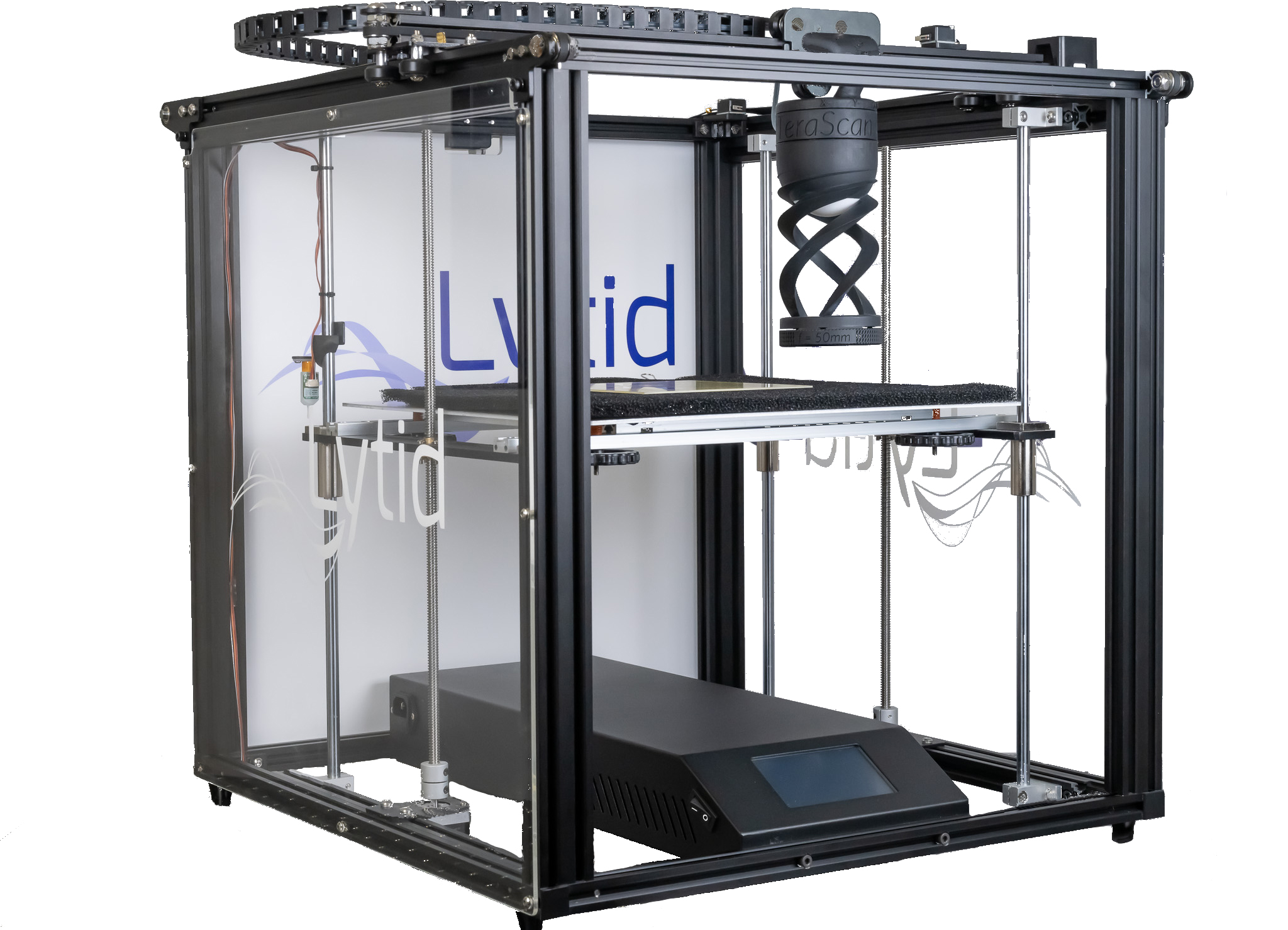

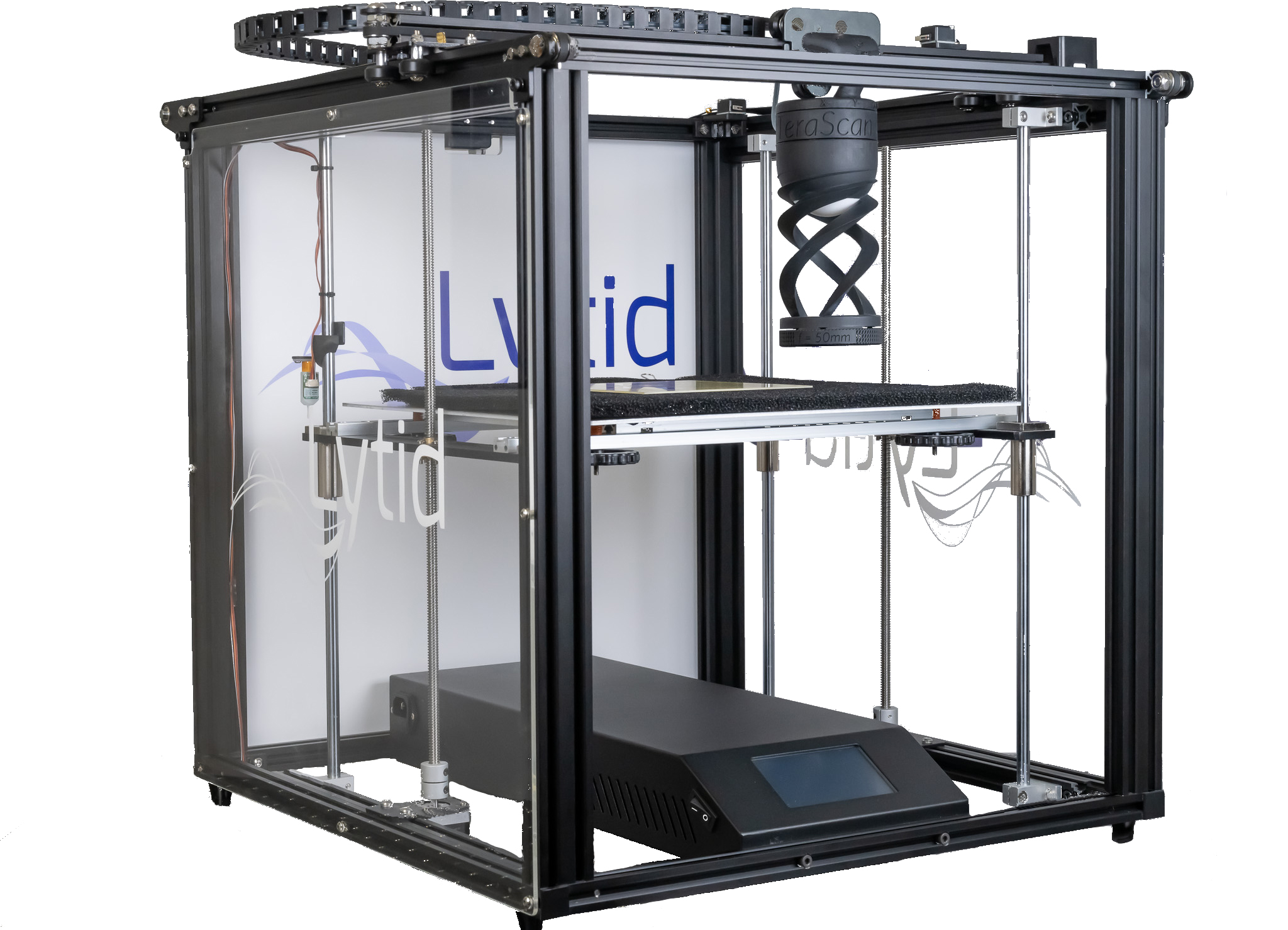

Our solution : TeraScan

TeraScan product line offers unparalleled versatility and performance. It comes equipped with:

> Motion vector

> THz optics

> FMCW radar sensors

> Software suite

Features

Modular design

The TeraScan features interchangeable units for the scanner, sensor, and optics. The scanner unit offers three geometries with automated COBOT-based controls or through a 3-axis translation structure, depending on the geometry of the object under inspection.

TeraScan Frame

TeraScan Arm

TeraScan Arm long range

The choice of sensor operating frequency range is tied to the expected performance on the material being inspected, required dynamic range, and expected resolution. Sensors are available in three different operating frequencies: 120 GHz, 240 GHz, and 300 GHz. Lastly, the available optics allow for adjustment of working distances.

Interchangeable radar sensors and lenses

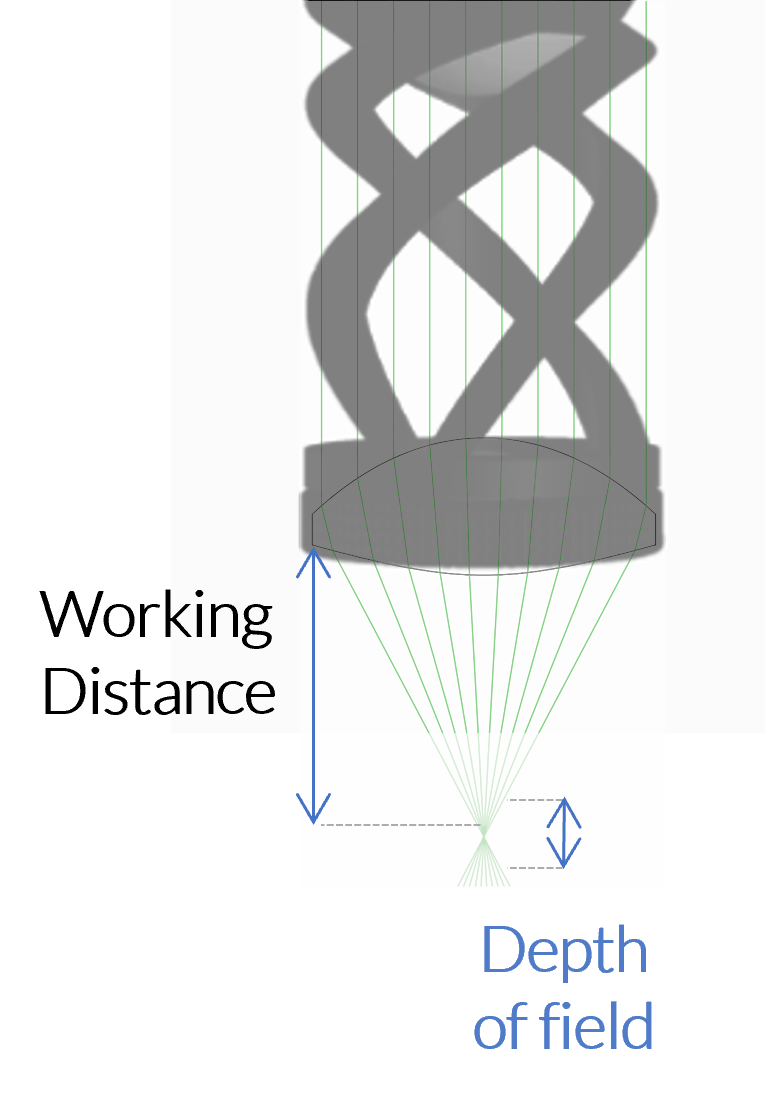

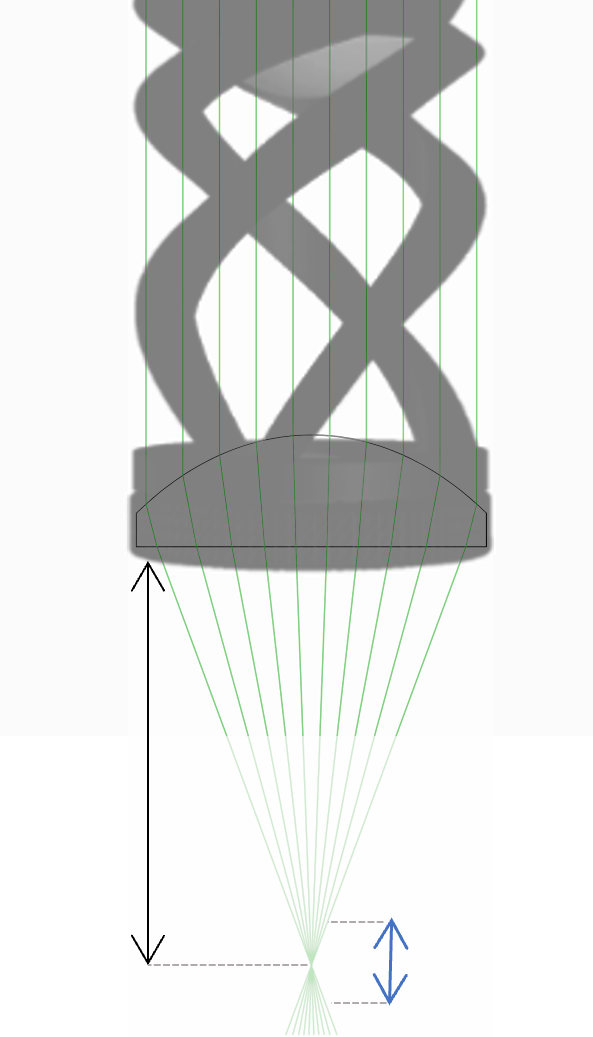

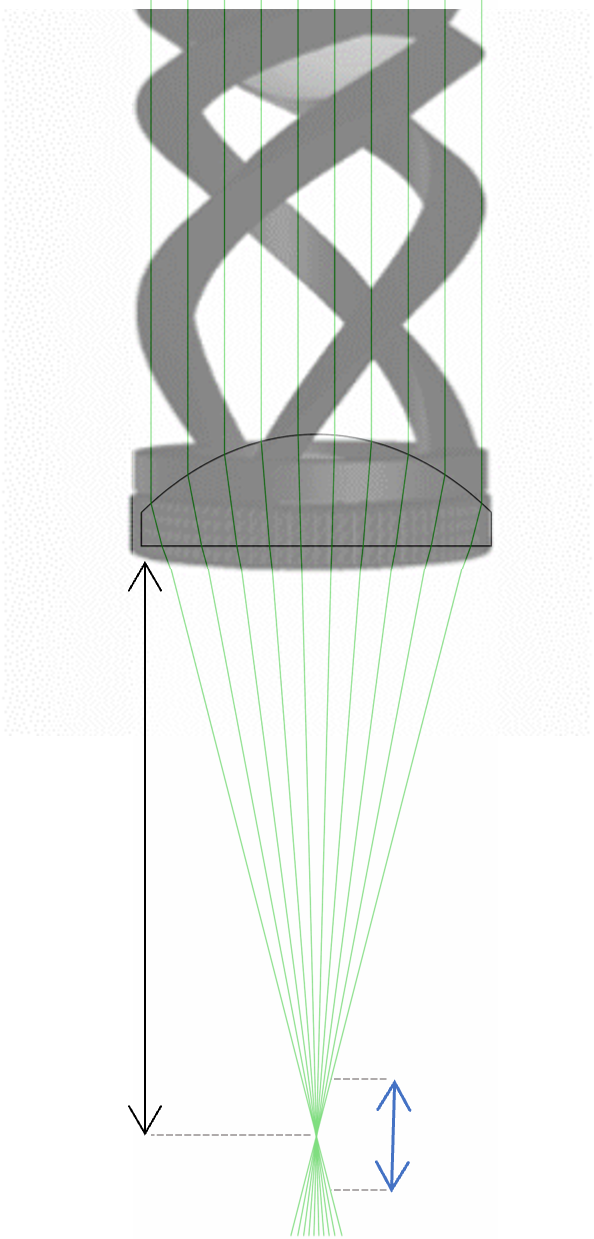

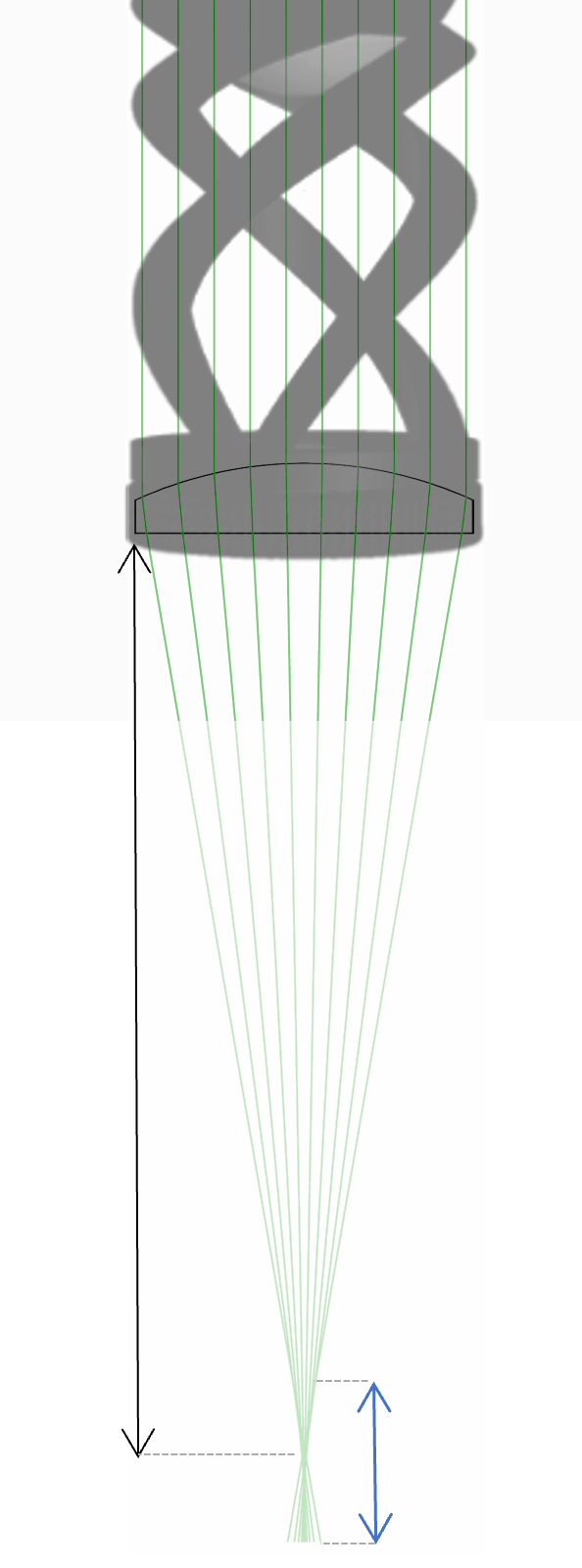

Helicoidal head with a sensor and two lenses, from top to bottom

Our expertise guides you to find the optimal configuration for your inspection needs. Advanced configurations can be found on:

Sensor auto-calibration

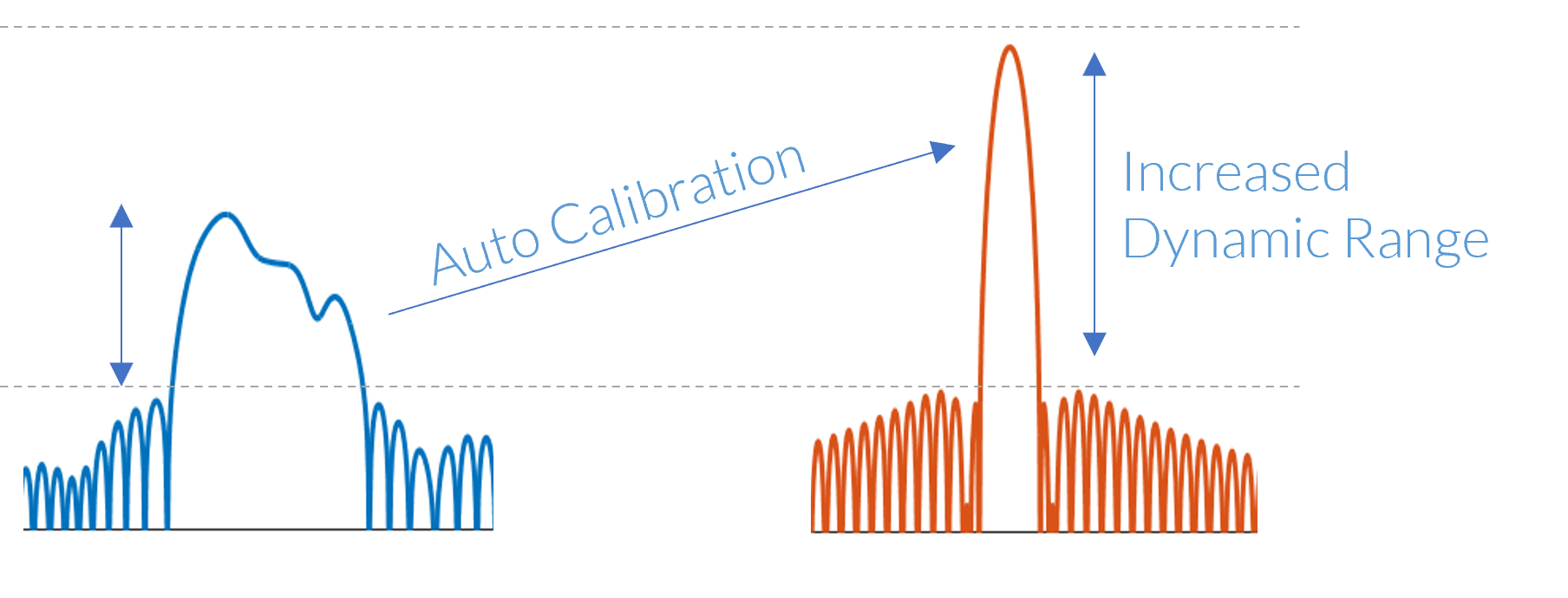

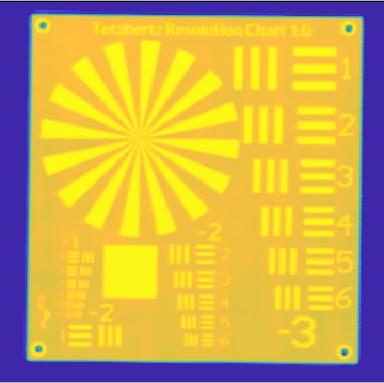

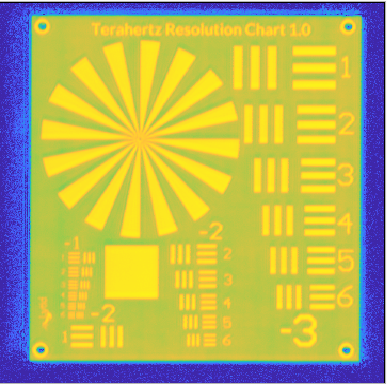

To reach optimal performances in terms of dynamic range and measurement repeatability with all sensors, each measurement procedure initiates with a fully automated calibration of the used transceiver. Either through the 3-axis plotter or through the COBOT arm control, such a quick calibration procedure ensures typically more than 60 dB dynamic range.

Reference and background autocallibration

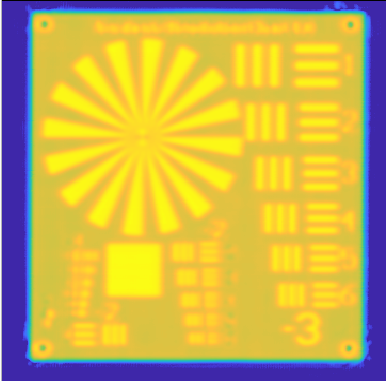

The signal before (left) and after (right) auto-calibration

Simplified Image Aquisition and Enhanced Data Processing

Terascan comes with a dedicated software that is designed to simplify the use of the system and enable advanced visualizations. The software has a user-friendly interface that makes it easy to handle the scanner and configure the imaging procedure. It also displays real-time signal visualization and ongoing scan visualization and progress. Teravisio is an add-on software that provides advanced data processing for 3D visualization of samples and image exports. The user can access raw measurement data sets for tailored post-processing.

Data aquisition software: TeraScan Easy

Motion Vectors Specifications

| Models/Specs | Frame | Arm | Arm long range |

|---|---|---|---|

| Mode of operation | FMCW sensing | FMCW sensing | FMCW sensing |

| Type | x-y-z plotter | Automated 6-axis robotic arm max reach 400 mm | Automated 6-axis robotic arm max reach 700 mm |

| Imaging area (mm) | Max 300x300 | Typ 400x400 | Typ 600x600 |

| Minimal step (mm) | 0.5 | 0.25 | 0.25 |

| Sample height (mm) | up to 150 | X | X |

| Max footprint (H x W x L) (mm) |

650x650x650 | 500x800x800 | 800x1500x1500 |

| Required interface connectors | USB2.0*3 | USB2.0*2 RJ45 Ethernet socket |

USB2.0*2 RJ45 Ethernet socket |

Sensors Specifications

| Models/Specs | TeraScan 100 | TeraScan 200 | TeraScan 300 |

|---|---|---|---|

| Frequency (THz) | 0.12 | 0.24 | 0.3 |

| Minimal lateral resolution (mm) | 1.8 | 0.9 | 0.7 |

| Working distance (mm) | 50, 75, 100 150 | 50,75, 100, 150 | 50, 75, 100, 150 |

| Acquisition rate (Pixels/s) | 40 | 12.5 | 12.5 |

| Typ. dynamic range (dB) | >50 | >50 | >40 |

Data Aquisition Software

TeraScan Easy ©

3D data acquisition software

-

-

Setup scan parameters

-

Real-time monitoring

-

Access to raw data

-

Automated reference and background acquisition

-

Visualization Software

TeraVisio Basics ©

3D visualization software

-

C-scan (X/Y slices)

-

A-scan and B -scans visualizations

-

Depth explorer slider

-

Simplified image export

-

Simplified raw data loading

-

Integrated data processing

TeraVisio Advanced ©

3D advanced visualization software

All TeraVisio basics features

+ Customizable interface for tailored display

+ Comparative visualization

+ A, B and C scans selections

TeraScan Use Cases

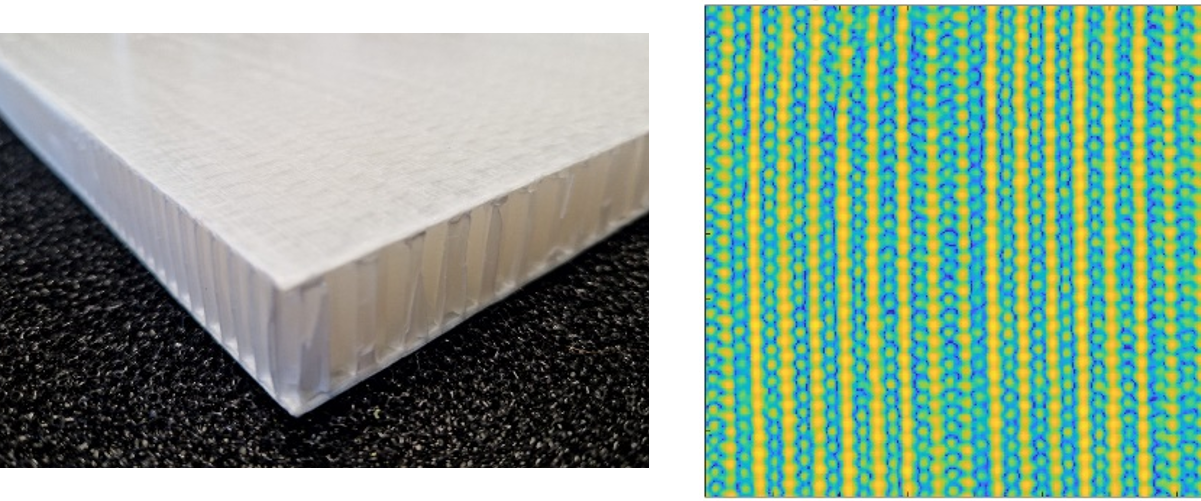

Honeycomb GFRP Composite Structures

- Type of defects: Honeycomb structural integrity & GFRP delamination

- Additional: Internal water content, foreign bodies detection & alveoli inspection

FIberglass composite quality

- Type of defects: inclusion and delamination detection

- Additional:Visualization of a honeycomb structure

Complex Polymer structures

- Type of defects: Watertightness of a glue seal & defects within polymer plates structure

- Additional: Sample integrity, defect detection, health monitoring & volumetric metrology

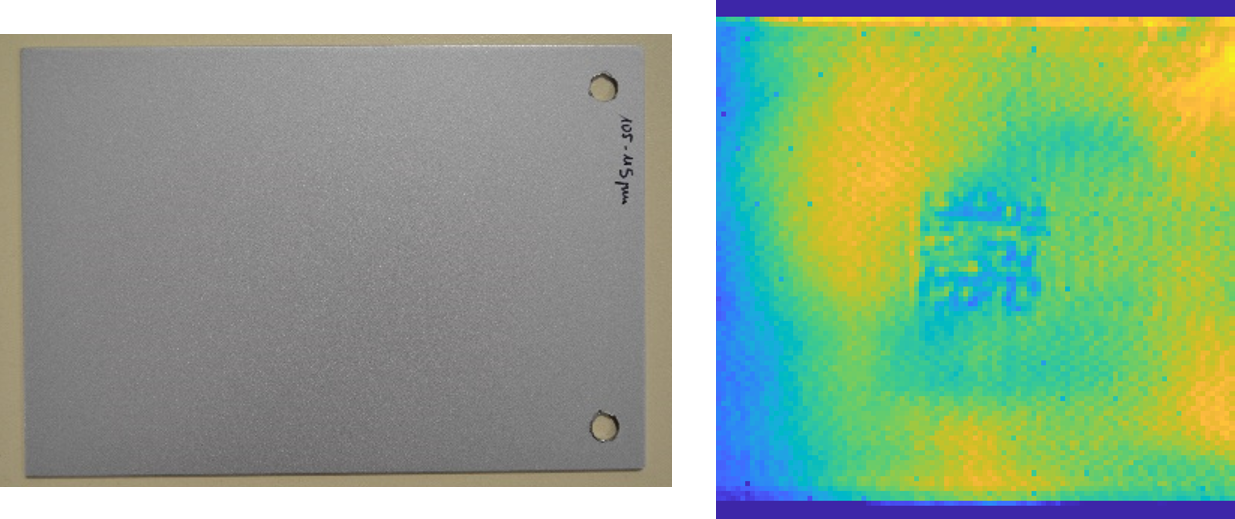

Corrosion protected metallic plate

- Type of defects: Corrosion marks under protective coating

- Additional: Coatings delamination, impacts marks & metallic surface quality through protective layersy

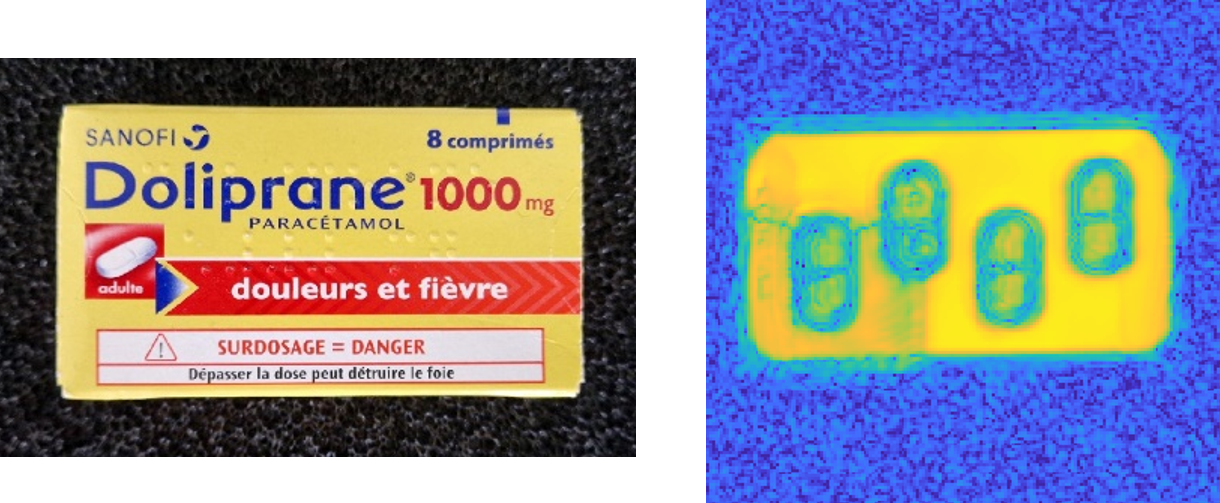

Pharmaceutical packaging

- Type of defects: Missing pill within full packaging & Leaflet position

- Additional: No alteration of the active molecules, internal & external packaging inspection, packaging seals integrity & pills count

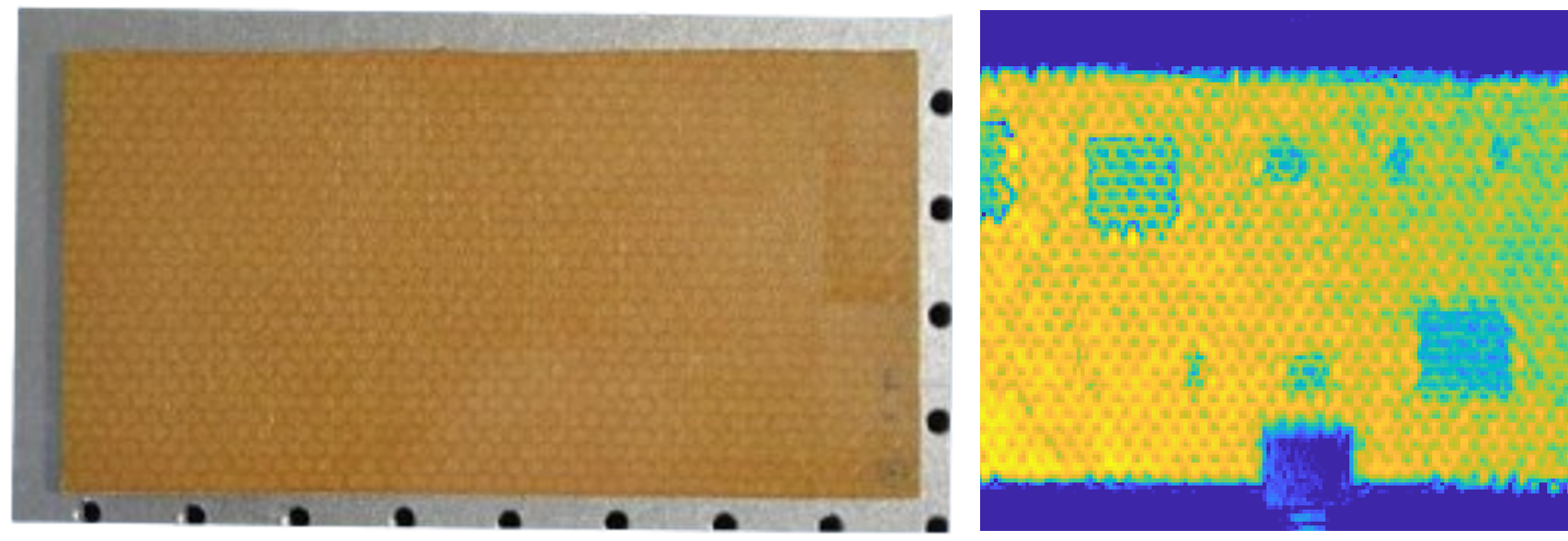

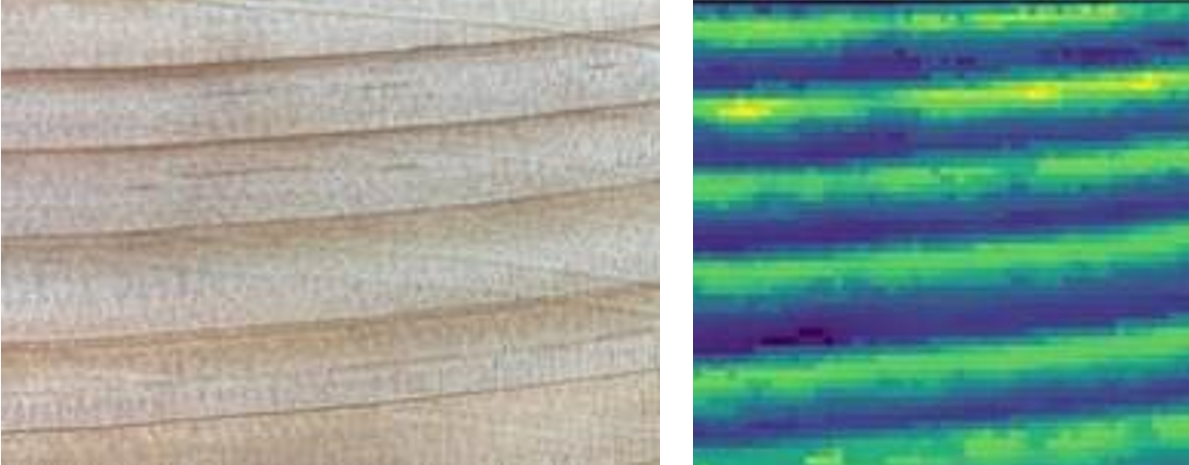

Wooden materials and composites

- Sensing capability: Density mapping, water content & structural inspection

- Additional: Inhomogeneities detection, fieldbus node dimensioning & inner structure inspection

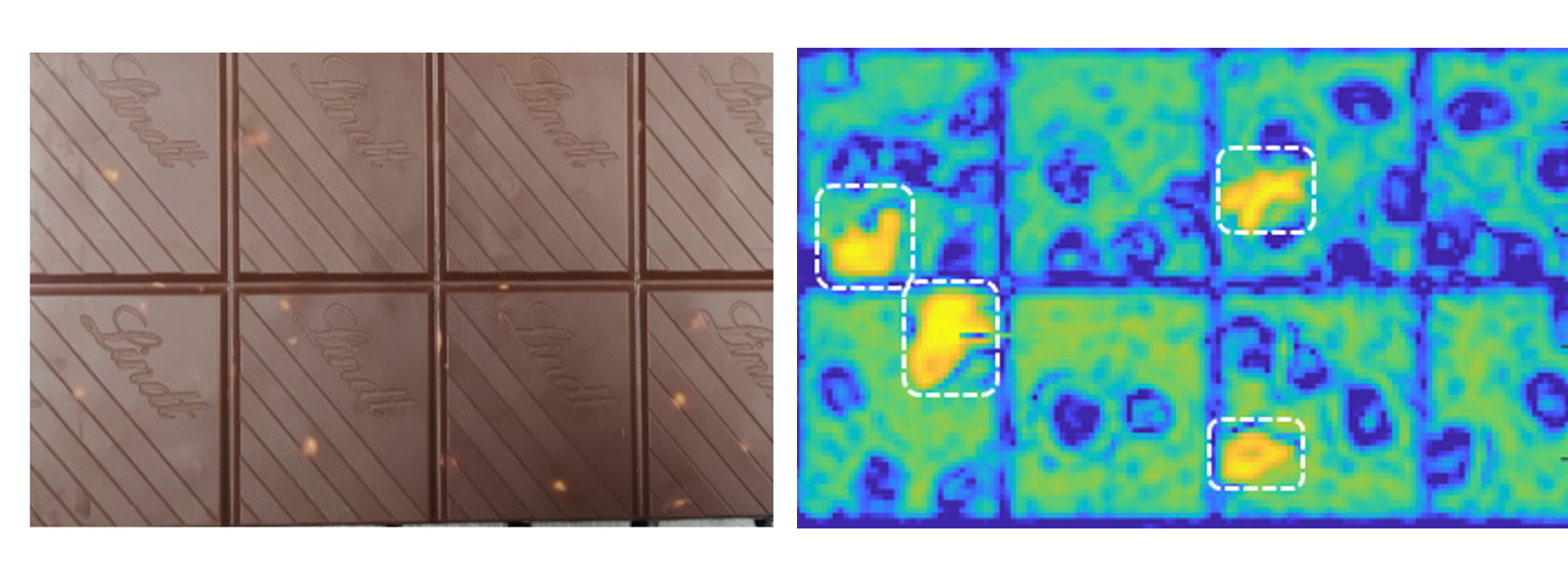

Foreign bodies detection in Food

- Type of defects: Glass behind the chocolate

- Additional:Hazelnut

1. Choose your motor vector

Frame

x-y-z motorized translation stage

300 mm × 300 mm typ. scanning area

Arm

6-axis collaborative scanning robotic arm

Max reach 400 mm

400 mm × 400 mm typ. scanning area

Arm long range

6-axis collaborative scanning robotic arm

Max reach 850 mm

750 mm × 750 mm typ. scanning area

2. Choose your sensor frequency

TeraScan 100 | Lite

Frequency band 120 GHz

Bandwidth 20 GHz | 6.2 GHz

Pixel aquisition rate 30 Hz

Typ.Dynamic range >50 dB

Lateral resolution 1.8 mm

TeraScan 200

Frequency band 240 GHz

Bandwidth 37 GHz

Pixel aquisition rate 20 Hz

Typ.Dynamic range >65 dB

Lateral resolution 0.9 mm

TeraScan 300

Frequency band 300 GHz

Bandwidth 27 GHz

Pixel aquisition rate 20 Hz

Typ.Dynamic range >40 dB

Lateral resolution 0.7 mm

3. Choose your optics

Lens f= 50 mm

Lens f= 75 mm

Lens f=100 mm

Lens f=150 mm

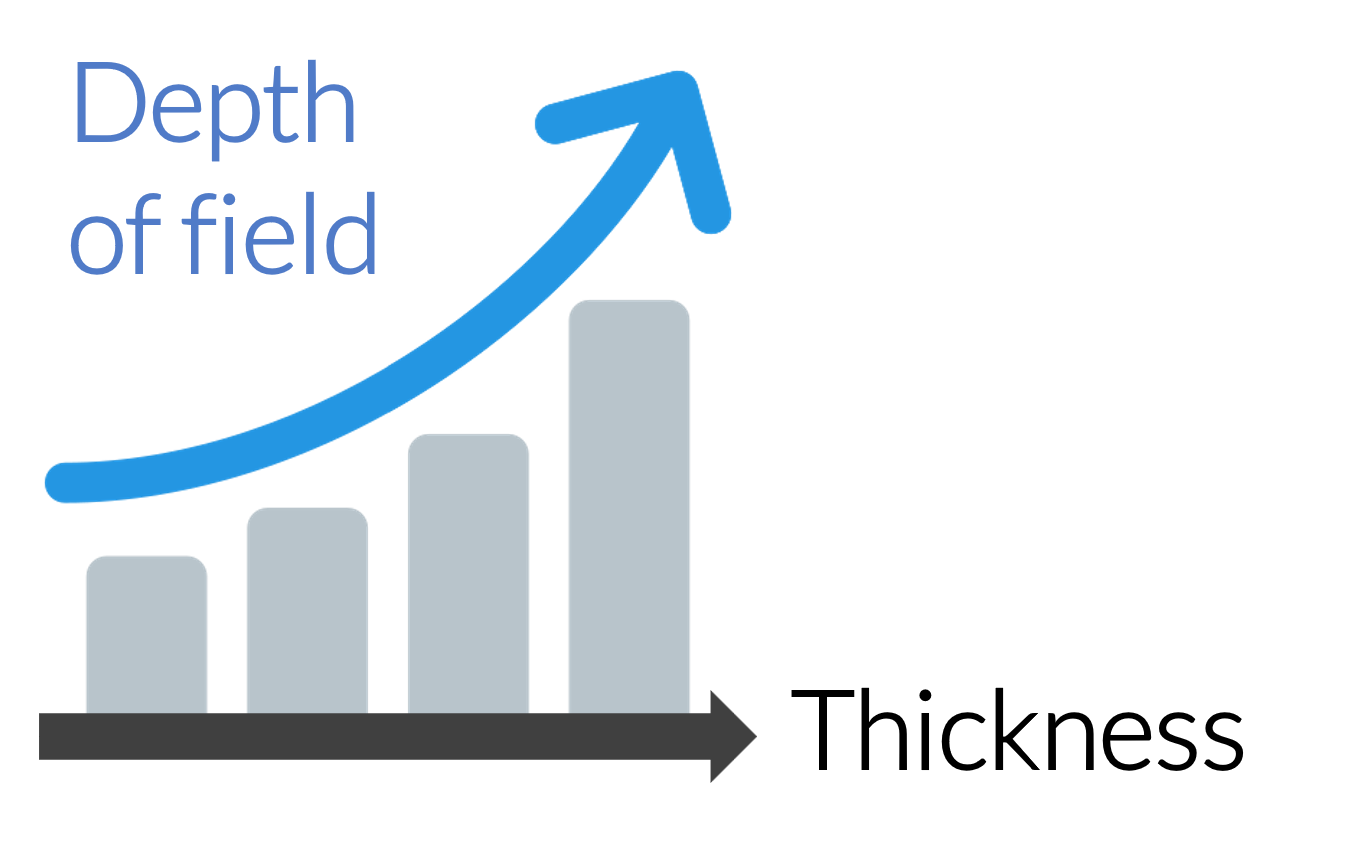

Remark: Working distance refers to the distance between the last lens and the target object being observed. Lower working distances often allow for wider numerical aperture (NA) lenses, leading to better resolution potential. However, for thick samples, larger working distances are key. This gives you a larger depth of field.

4. Choose your advanced visualization software

TeraVisio Basics

- C-scan images (X/Y slices)

- A-scan and B-scan visualizations

- Depth explorer slider

- Simplified raw data loading

- Integrated data processing

- Simplified image export

TeraVisio Advanced

All TeraVisio Basics features

+ Customizable interface for tailored display

+ A, B and C-scans selections

+ Comparative visualization